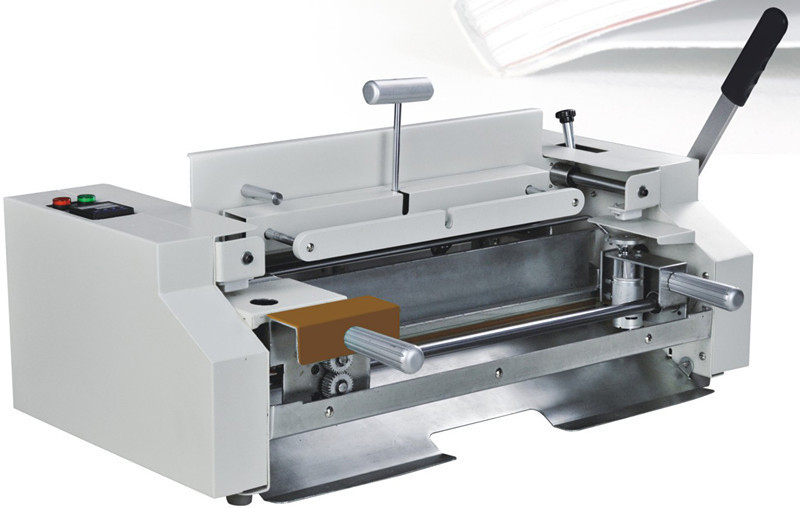

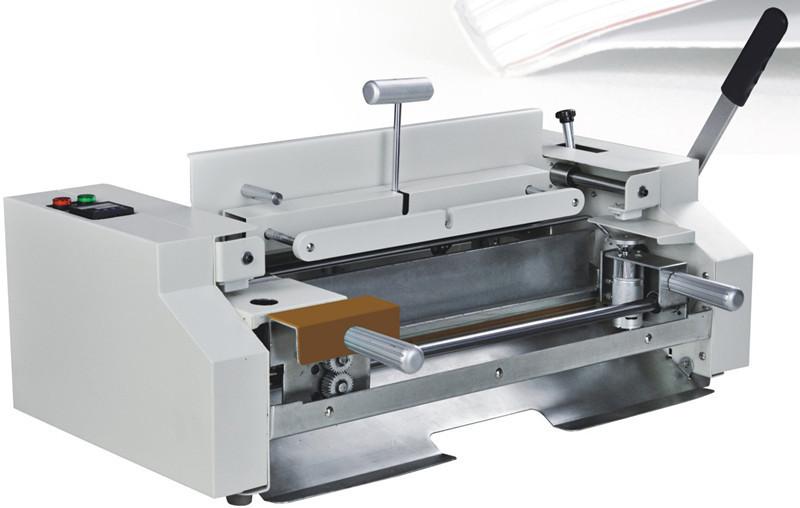

Manual cutting ,gluing and binding system(W300)

Manual cutting ,gluing and binding system(W300)

| Categories | Glue binding machine (perfect binder) |

|---|---|

| Brand | SUPU |

| Model | W300 |

| Max binding width | 360mm |

| Max binding thickness | 45mm |

| Binding speed | 40-60 books/hours |

| Power | 110V-240V/60/50HZ/350W |

| Heating time | 20 min |

| Machine dimension | 690x380x500mm |

| Machine weight | 29kg |

| Packing | 1pc/case |

| FOB port | Ningbo/Shanghai |

| Terms of Payment | T/T |

| Update Time | Apr 19,2024 |

Desk-top perfect glue binding machine W300

The desktop type manual binding machine can be operated by manually pushing the rubber pot during operation. It is suitable for small-volume production of books, tenders, document binding, etc. Before the book is made, it is necessary to press the cover strips (can be completed with a creasing machine). To determine the binding position of the cover and the inner page, then put the manual glue machine on the device, clamp, flip the handle, and let the back part of the book up, in order to make the plastic cup and the back of the book fully contact, so the book back up, push in the plastic pot During the brushing process (fan-shaped glue), give a gentle pressure on the back of the book, so that each piece of paper is glued, so that the book that is glued out is firmer, firmer, not loose, and does not drop pages.

Manual operation gluing

Manual cutting and manual binding

Operation on desk-top

Machine dimension: 690x380x500

Machine weight: 29kg

Maximum:

Thickness 34mm

Punching up to 30 sheets

Max.thickness 50mm

Thickness 34mm

Punching up to 30 sheets

Max.thickness 50mm

DESK-TOP PERFECT BINDER, AND OPERATION SIMPLE.

Address:

Tangpu Industrial Park, Anji, Huzhou City, Zhejiang Province, 313300. CHINA

PHONE:

+86-571-88963565

E-MAIL:

hzsp@hzsuper.com

- Tel

- *Title

- *Content