Heavy duty electric coil binding machine (SUPER47E PLUS)

| Share | |

|---|---|

| Categories | Electric spiral binding machine |

| Brand | SUPU |

| Model | SUPER47E PLUS |

| Model | Super47 Eplus |

| Brand Name | SUPU |

| Place of origin | Hangzhou,china |

| Width | 300mm |

| Punching thickness | 25 sheets |

| Pitch | 6.287mm |

| Disengagement punch pins | 47 |

| Number of punch pins | 47 |

| Binding thickness | 180 sheets |

| payment | T/T |

| FOB port | Ningbo/Shanghai |

| Terms of Payment | L/C, T/T, Western Union |

| Update Time | Mar 7,2026 |

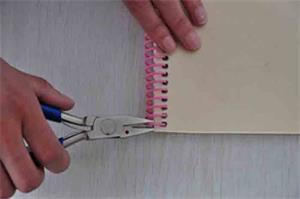

Heavy duty electric coil binding machine

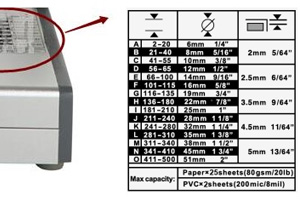

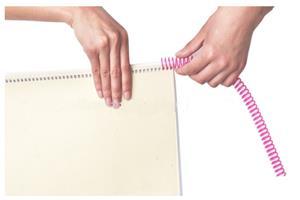

Electric binding makes coil binding fast, easy and professional. Electric inserting can save your time and improve binding ability. Disengagement dies can accept multiple paper size.Document measurement aid to select proper coil size by your sheet thickness. Alloy construction make it quality,durable and stable, keep long life for machine

Electric Punching up to 25 sheets 70g paper each time

Punching A4 format,11'' size paper.

Binding documents up to 180 sheets.

Die on request pitch: 3:1 4:1 6 mm

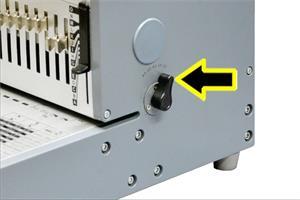

Side margin is adjustable.

Maximum:

Max. bind up 180 sheets

Width 300mm

Punch up to 2--3mm

Document measure to determine which comb size to be used All aluminium construction make it durable and many years worry free High capacity waste container requires emptying less frequently

Address:

Tangpu Industrial Park, Anji, Huzhou City, Zhejiang Province, 313300. CHINA

PHONE:

+86-571-88963565

E-MAIL:

hzsp@hzsuper.com

- Phone

- *Title

- *Content